|

Conduct

Physical Experiments

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |

The in-vitro dingy and double dingy monitors are test fabrics models fabricated on commercial fabrics, used by detergency labs as test monitors to be washed/dried according to actual laundry practices around the world.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dingy Monitors: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

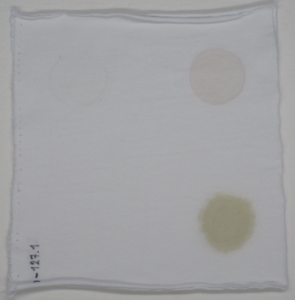

Example: Commercial machine washing process, following some specific Asian conditions, gentle cycle Before: wash 00

After: wash 15

|

Whiteness

Perception. Medium and

Long term. Code: DINGY_WM/ Specified

intended use: to represent

commercial new and worn (clean

dingy) white garments, in

which world�s consumers

evaluate whiteness attributes,

like prevention and

restoration, after multiple

consecutive household

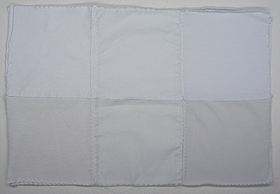

washing/drying processes One (1) monitor contains six (6) different fabric swatches. Three (3) original white commercial fabrics, plus their three (3) clean dingy versions There are six (6) different white fabric swatches per monitor. Three of them (first row) represents commercial white garments pre-washed in one cycle with a generic detergent with no dyes and fluorescent agents, and the others three (second row) represents their clean dingy versions after ten (10) cycles of washing/drying cycles, DINGY_CL. Clean dingy fabrics can follow different standard market realities (India, China, Latin America, Europe, USA or others) or customised specific realities according to client needs. This

standardised monitor contains

one piece of knitted cotton

100%, one piece of woven

poly/cotton 65:35, one piece of

knitted cotton/lycra 92:8, and

their clean dingy versions. Each

swatch of 15 cm X 15 cm, total

monitor of 30 cm X 45 cm. Selling

unit: per package of twenty five

(25) units Minimum

order: one (1) package of twenty

five (25) units Regular

price: US$ 50.5o / unit Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

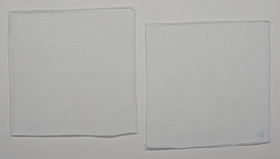

Example: Commercial machine washing process, following some specific Asian conditions, gentle cycle Before: wash 00

After: wash 01

|

Immediate

Whiteness and Initial

Cleanliness Perception /

Body and Ambient Soil

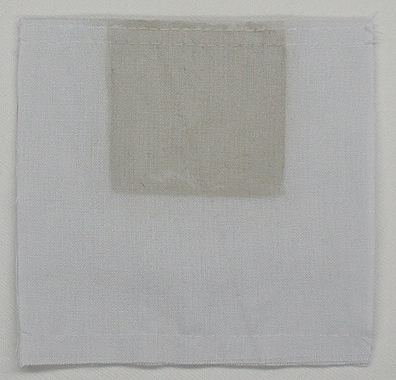

Removal Code: DINGY_SD/ Specified intended use: to represent commercial soiled worn (soiled dingy) white garments, in which world�s consumers evaluate immediate whiteness improvement, or immediate general cleanliness, after first household washing/drying processes One

(1) monitor contains three (3)

different fabric swatches.

Three (3) homogeneously soiled

dingy test fabrics There are three (3) different fabrics, soiled dingy test fabrics. In just one (1) soiling step, a clean dingy fabric DINGY_CL is soiled uniformly with a combination of fresh body and ambient soils. The final monitor is obtained after a total of eleven (11) washes. All fabric shows a yellowish or greyish or reddish cast pending on the combination of clays used in the process. Soiled dingy fabrics can follow different standard market realities (India, China, Latin America, Europe, USA or others) or customised specific realities according to client needs. This

standardised monitor contains

one piece of knitted cotton

100%, one piece of woven

poly/cotton 65:35, one piece of

knitted cotton/lycra 92:8,

soiled dingy versions. Each

swatch of 15 cm X 15 cm, total

monitor of 15 cm X 45 cm. Selling unit: per package of twenty five (25) units Minimum order: one (1) package of twenty five (25) units Regular

price: US$ 54.5o / unit Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Example: Commercial machine washing process, following some specific Asian conditions, gentle cycle Before: wash 00  After: wash 01  Before: wash 00 After: wash 01

|

Cleanliness

Perception. Stains Remotion Code: DINGY_TN/XX/ (specific for each stain or monitor) Specified intended use: to represent commercial stained worn (stained dingy) white garments, in which world�s consumers evaluate cleanliness in the garment context, by remotion of specific stained areas after first household washing/drying processes One (1) monitor contains one or several stained areas immersed in a dingy substrate that surrounds it This is a dingy test fabric with a localised stained area(s) that represents a stained worn garment ready to wash. Several relevant stains are applied manually at real concentrations levels onto shaded clean dingy fabrics DINGY_CL, wich is obtained previously after a total of ten (10) cycles of washing and drying. Surrounding dingy fabrics can follow different standard market realities (India, China, Latin America, Europe, USA or others) or customised specific realities according to client needs E. Environmental Soils Monitors

Each monitor dimension: ~20 cm X ~22 cm Selling

unit: per package of twenty five

(25) monitors Minimum order: one (1) package of twenty five (25) monitors

Regular price: US$ 21.7o /

monitor F. Food and Drink Soils Monitors F.1.

Combination of three (3) drink

soils and one (1) dingy context

in one monitor

Each monitor dimension: ~20 cm X ~22 cm Selling

unit: per package of twenty five

(25) monitors Minimum order: one (1) package of twenty five (25) monitors

Regular price: US$ 21.7o /

monitor F.2.

Combination of three (3) food

soils and one (1) dingy context

in one monitor

Each monitor dimension: ~20 cm X ~22 cm Selling

unit: per package of twenty five

(25) monitors Minimum order: one (1) package of twenty five (25) monitors

Regular price: US$ 21.7o /

monitor F.3.

Combination of three (3) food

soils and one (1) dingy context

in one monitor

Each monitor dimension: ~20 cm X ~22 cm Selling

unit: per package of twenty five

(25) monitors Minimum order: one (1) package of twenty five (25) monitors

Regular price: US$ 21.7o /

monitor Individual

Stains in Monitors (not for

collar&cuffs or armpit) Monitors with individual stains onto a dingy surrounding are produced on knitted cotton 100% or woven poly/cotton 65:35, clean dingy fabrics. Each monitor dimension of ~11 cm X ~12 cm Selling

unit: per package of fifty (50)

units of each stain Minimum order: one (1) package of fifty (50) units of each stain Regular

price: US$ 7.9o / unit Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Example:  |

Olfactive

Cleanliness Perception.

Malodorous Control A unique way to measure consistently olfactive cleanliness under a consumer relevant olfactive context. Perception

of a garment's olfactive

cleanliness in real consumer

scenarios is considered one of

the primary elements that

impacts the purchase behaviour

of laundry products. That

perception results from the

complex and variable

interactions among fabrics,

odours, olfactive scenarios,

and consumers, which are often

chaotic. Environmental

Malodour Monitors:

Body

Malodour Monitors:

Food

Malodour Monitors:

These dingy standardised monitor are prepared on: Each monitor of 10 cm X 10 cm Selling unit: per package of twenty five (25) units Minimum order: one (1) package of twenty five (25) units Regular price: US$ 15.8o / unit

Malodour

Test Monitor - Brochure |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Example:  |

Colour

Care Perception. The

Coloured and Dingy White

Monitor Colour-care perception with simultaneous local contrast effects: Code: DINGY_CC/ Specified

intended use: to represent

commercial worn (clean dingy)

coloured garment that combines

white and colour areas, in

which world's consumers

evaluate colour-care benefits

of laundry products after

consecutive household

washing/drying processes One (1) monitor contains six (6) fabric swatches, four (4) coloured, one (1) original white and one (1) clean dingy white Current trend in the garment industry is the combination of colours and whites strips. One colour cloth is now the exception. This textile trend is a real challenge from the colour-care perspective, because now the problem is not only to preserve colours but also to preserve the whites areas, because if both are part of the visual scenario, there is full interaction between them. Detrimental changes in the whites areas will affect significantly the colour-care perception due to local contrast effects, colour will be perceived dull. This new dingy monitor from CONSUMERTEC offers for the first time a practical standardised alternative to technology innovators to experiment in the field of colour care in consumer relevant terms. Contrast effects or chromatic induction are very well know phenomenology in vision science but not implemented in the detergency industry, due to the regular use of basic colorimetric procedures. Algorithms to compute this visual effect needs a more complex approach. CLLS collection of algorithms coded by CONSUMERTEC offers this capability grounded on very recent advances in numerical models to represent more realistic interaction between white and colour in the same surface visual scenario. The monitor contains four (4) coloured swatches which are new original fabrics, commercial or standardised (AISE standards). Additionally it contains one (1) white swatch which is a new original fabric and another one (1) which is a clean dingy swatch, DINGY_CL, prepared according to relevant consumer realities, i.e. it represents a clean dingy white garment after ten (10) cycles of washing/drying cycles following different standard market realities (India, China, Latin America, Europe, USA or others) or customised specific realities according to client needs. This standardised monitor is prepared on cotton 100%. Each monitor of 22 cm X 40 cm. Selling unit: per package of twenty five (25) units Minimum order: one (1) package of twenty five (25) units Regular price: US$ 22.6o / unit Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

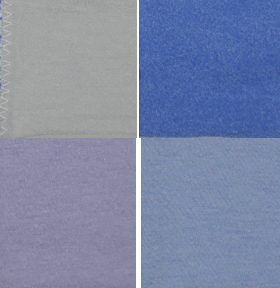

Original coloured monitors (light grey on cotton, blue on cotton, light violet on poly/cotton and light blue on poly/cotton):  Abrasion process:  Aged monitors with fabric damage:  Monitors after a multi washing test:  |

Colour

Restoration Perception. The

Dingy Aged Coloured Monitor

with Fabric Damage To measure fabric-care attributes of laundry products: Code: DINGY_CD/ Specified

intended use: to represent

commercial worn coloured

garment with fabric damage

after consecutive cycles of

washing/drying and abrasion,

in which world's consumers

evaluate fabric-care benefits

of laundry products after more

consecutive household

washing/drying processes One

(1) monitor contains four (4)

fabric coloured swatches, two

(2) original or new, two (2)

aged with fabric damage The majority of everyday coloured clothes are not new. They have become noticeably different to similar new garments after successive cycles of washing and drying after use. Some level of fabric damage appears, specially pilling in cotton and poly/cotton fabrics, which is formed due to rubbing or abrasion during normal wear: the �aged garment�. Some laundry technologies have shown the potential to both exacerbate the fabric damage or restore, in some level, the garment�s appearance. In line with this, CONSUMERTEC has developed these unique kind of test monitors by a combination of ten (10) cycles of washing/drying with soil ballast, and abrasion using robotics arms to rub fabrics in a full controlled way. Coloured aged monitors, original and aged, are offered to assist R&D efforts to verify/discover brand�s claims or to balance consumer benefits with technologies cost. It is recommended to use instrumental analysis to quantify changes on colour appearance and visual sensory analysis to quantify changes on pilling content. One unit of the monitor contains four (4) commercial swatches:

Selling unit: per package of twenty four (24) units. ninety six (96) total swatches: forty eight (48) original swatches and forty eight (48) aged swatches Minimum order: one (1) package of twenty four (24) units Regular price: US$ 20.5o / unit. US$ 492.oo / package Instrumental data (colour change) from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Double Dingy Monitors: |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Dingy collar&cuff:

Double dingy collar&cuffs:

|

Collar and Cuffs Stained Monitor. Dingy and Double Dingy Code:

Dingy_TN/CP/ or D-Dingy_TN/CP/ Specified intended use: to represent commercial stained worn (stained dingy) white garment collars, in which world�s consumers evaluate cleanliness in the collar context, by remotion of the specific stained area after first household washing/drying processes Dingy version contains one (1) double-layered fabric swatch with two (2) areas: collar and cuff stained area immersed in a dingy substrate that surrounds it Double dingy version contains one (1) single-layered fabric swatch with two (2) areas: collar and cuff dingy stained area immersed in a dingy substrate that surrounds it Consumer cleanliness assessment of laundry product is not the same around the world, but it has been found that some washing problems are nearly the same despite different cultures and habits. Consistently, remotion of easily perceived stains present on white collar and cuffs constitute one of the icons linked to final consumer value delivered by laundry products. Unfortunately this simple cleanliness perception fact from the consumer point of view, is a very complex process from the R&D perspective, not only due to the complexity of the inorganic and organic constituents of the stain, but also due to the interaction of different fabric surroundings (the area in direct contact with the skin and the rest of the collar area) on final consumer cleanliness perception. CONSUMERTEC, using a custom-built non-contact mini spectrofluorimeter, has characterised the absolute spectrometric properties of very small fabric areas (less than 6 mm2), like the strip-shaped remanent collar and cuffs stained area after some process of wash, and its fabric surrounding, as well as accurate determination of typical fluorescence spectroscopy properties like: quantum absorptance function, quantum yield, and total, reflected and luminescent radiation coming from the fabric and capable to reach consumer's eyes. Our approach is a test fabric with a stained area on different dingy surroundings that simulate a worn white collar. with one area of fresh stain in case of dingy version or a dingy stain in case of double dingy version that mimic the combination of body and ambient soil, specifically a mixture of components of four groups: sweat gland secretions, sebaceous gland secretions, dead skin cells, and ambient particle and dust. The final monitor is obtained after a total of ten (10) washes and one (1) complex staining step. Surrounding dingy fabrics can follow different standard market realities (India, China, Latin America, Europe, USA or others) or customised specific realities according to client needs. 1. Dingy version:

2. Double dingy version:

Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

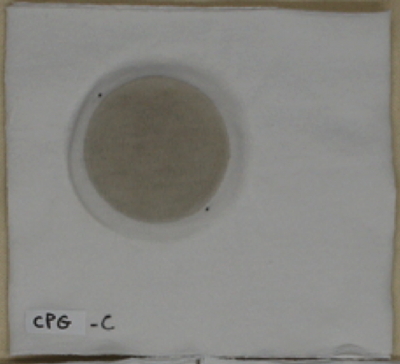

|

Double dingy armpit on

poly/cotton:

Double dingy armpit on cotton:

|

Armpit Stained Monitor. Double Dingy Code: D-DINGY_TN/AX/ Specified intended use: to represent commercial stained worn (stained dingy) white garment armpit area, in which world�s consumers evaluate cleanliness in that area context, by remotion of the specific stained area after first household washing/drying processes One (1) monitor contains one (1) fabric swatch with two (2) areas: armpit stained area immersed in a dingy substrate that surrounds it Probably is the second more problematic and common body stain in the consumer market and from the consumer point of view, a truly headache for the person in charge of laundry. From a technical point of view this is really complex stain that results from the interaction of deodorant product ingredients with underarm human secretions and proteinaceous residues, under oxidative conditions at certain temperatures, in a continuous cycles of wearing and washing. Our approach has been to model and simulate consumer realities in order to obtain a standardised stain with relevancy to different market scenarios.The visible stain is generated after three (3) cycles of staining and washing, onto a clean dingy fabric. The final monitor is obtained after a total of thirteen (13) washes. Relevancy depends on different commercial deodorants present in the market, and different surrounding fabric's dingy conditions, which in turn can follow different standard market realities (India, China, Latin America, Europe, USA or others) or customised specific realities according to client needs.

Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Double dingy menstrual fluid:

Double dingy socks:  Double dingy urine-related:  Double dingy pillow:  |

1.

Underwear Liner with

Menstrual Fluid. Double

Dingy Code: D-DINGY_TN/MF/ Combination

of blood and proteinaceous

material

2.

Socks. Double Dingy Code: D-DINGY_TN/SS/ Combination

of particle inorganic and

proteinaceous material

3.

Urine-related area. Double

Dingy Code: D-DINGY_TN/UR/ Combination

of electrolytes and organic

non-fluorescent and

fluorescent dyes

4.

Pillow. Double Dingy Code: D-DINGY_TN/PW/ Homogeneous

soiled area (not focal stained

area) by a combination of

fatty, inorganic and

proteinaceous material

Detergency data from these monitors can be processed-analysed-visualised using the web app Laundry-VR. More at: Laundry-VR link. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ready to order? or need assistance? .. please fill contact form here |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

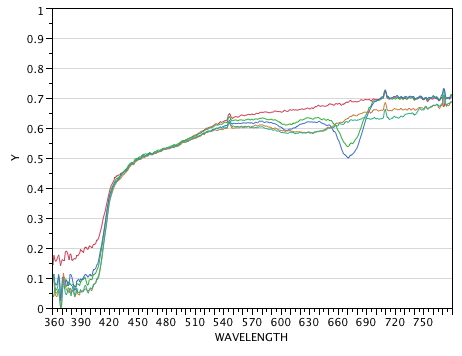

| Quality

Control and Duration

In order to ensure quality, test fabrics are subject to an instrumental evaluation control when each batch of fabric is completed; it is done according to the amount of fabric, which is recorded on a control chart. Coefficient of variance of less than 5% is guaranteed. The fabric should be stored in a dark place and at low temperatures (approximately 5�C). It is also recommended that the package be opened only when tests are to be conducted. Under these conditions, the fabrics will have a six-month life expectancy. Basic Delivery Conditions

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Home | Contact Us

Compared with conventional

non-consumer relevant technical

monitors, our dingy monitors are

fully washable in specific

domestic procedures in line with

what happens in the real market

to support total cleanliness

performance claims and to

balance formulations with a

consumer-centric approach.

Compared with conventional

non-consumer relevant technical

monitors, our dingy monitors are

fully washable in specific

domestic procedures in line with

what happens in the real market

to support total cleanliness

performance claims and to

balance formulations with a

consumer-centric approach.